5 years of metalworking exhibition!

We would like to thank all visitors, exhibitors and participants for making FaMeta25 a successful anniversary. After a creative break, we look forward to welcoming you back to Olching in 2027.

Exhibitors

Exhibitors from all areas of metalworking, as well as associated service providers are looking forward to meeting you.

Key facts

Cutting Machine Tools, Chipless Machine Tools, Additive Manufacturing, Precision Tooling, Metrology and Quality Assurance, Industrial Software, Accessories and Services.

Facts & Figures 2025

The Metalworking 2025 trade exhibition took place from 9 to 11 July.407

Companies were participating

67

Machines were demonstrated under voltage

450

Minutes of workshops & seminars

131

Experts were at your side

Press release

Fachausstellung Metallbearbeitung mit neuem Besucherrekord zum Jubiläum

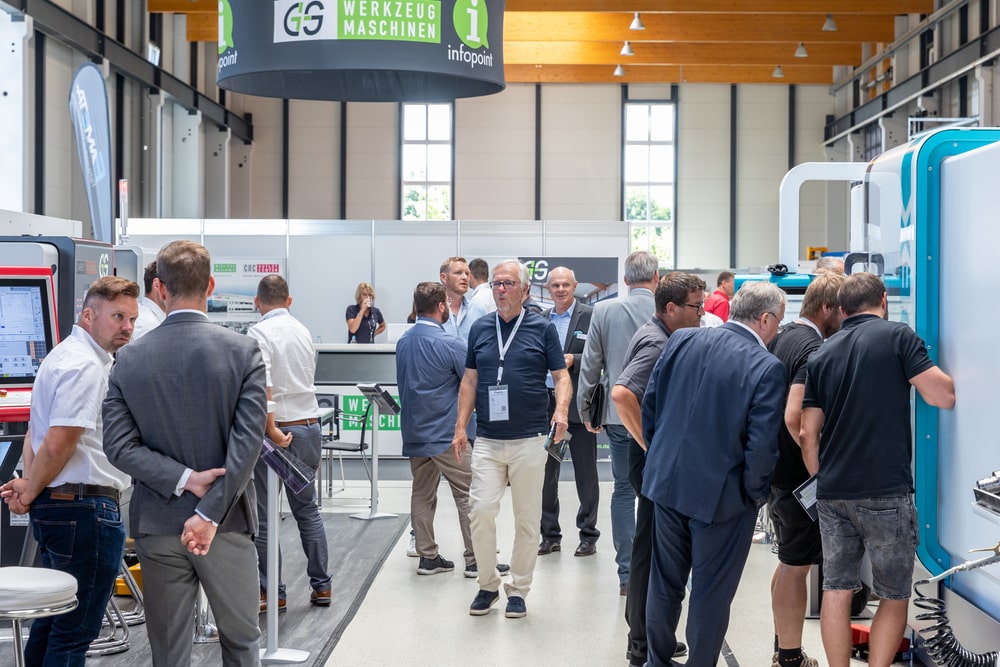

Von Mittwoch, 9. Juli bis Freitag, 11. Juli 2025 stand das CNC-Outlet Center in Olching im Zeichen der FaMeta: Die fünfte Veranstaltung in Folge erfüllte die Erwartungen der rund 400 teilnehmenden Betriebe. Die Fachgespräche rund um 67 vorführbereite Werkzeugmaschinen, praxisgerechte Automationslösungen, Peripheriegeräte, Industrial Software und Zubehör wurden auch in schwierigem Marktumfeld wahrgenommen und geschätzt.

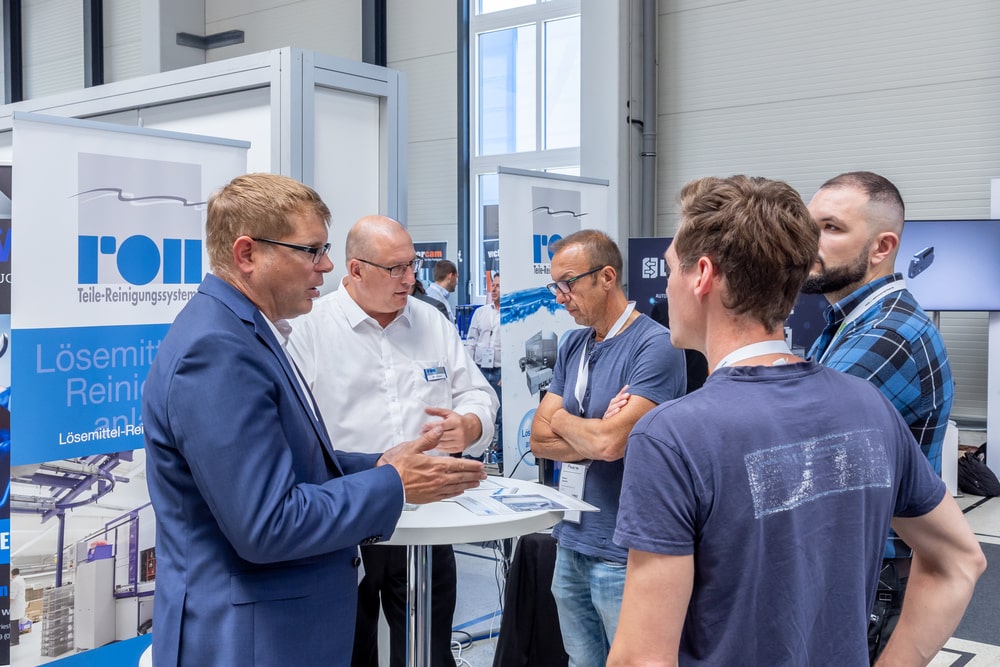

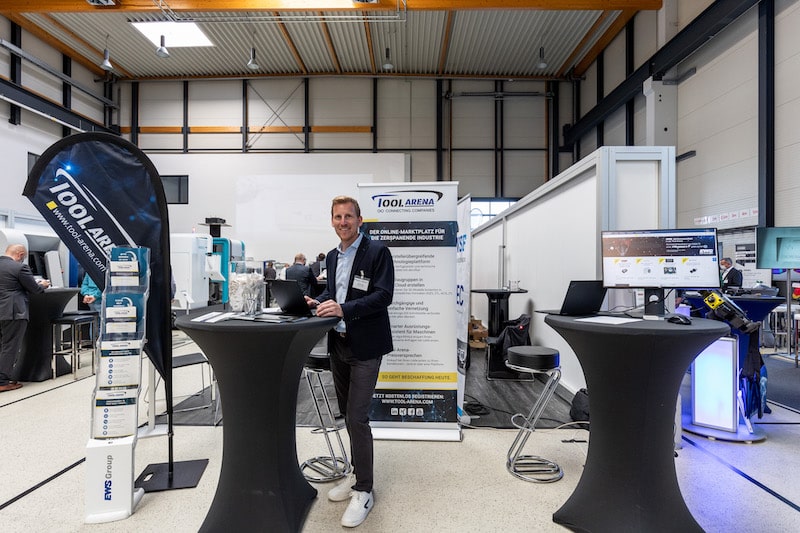

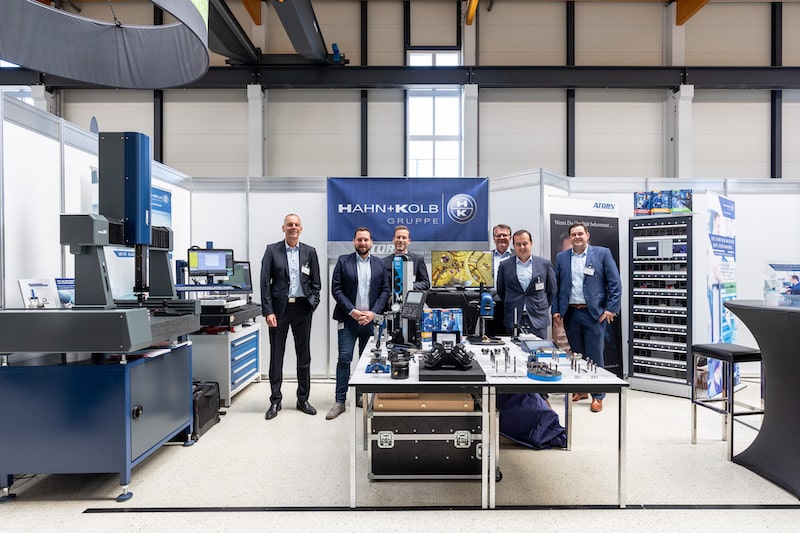

Well-known names such as Burkhardt+Weber, Chiron, EMAG, EWS Weigele, Geibel+Hotz, Hahn+Kolb, INDEX, Kunzmann, Tornos, Traub and Mazak have been attracting visitors to FaMeta for years - new exhibitors such as Hwacheon, DMG MORI, Diebold and Quant have also reported success. "We are delighted with the popularity of our products here," says Rainer Jilge, Area Sales Manager, Yamazaki Mazak. "With increasing coverage, FaMeta has developed into a real meeting place for the metalworking industry from southern Germany and parts of Austria over the past five years." Other machine tool exhibitors have a similar view: "For DMG's used machine sector, the trade fair is highly recommended," says Robin Koch, DMG Mori Used Machines. "In the centre of Bavaria, it offers a high quality of discussions in a regional and manageable setting."

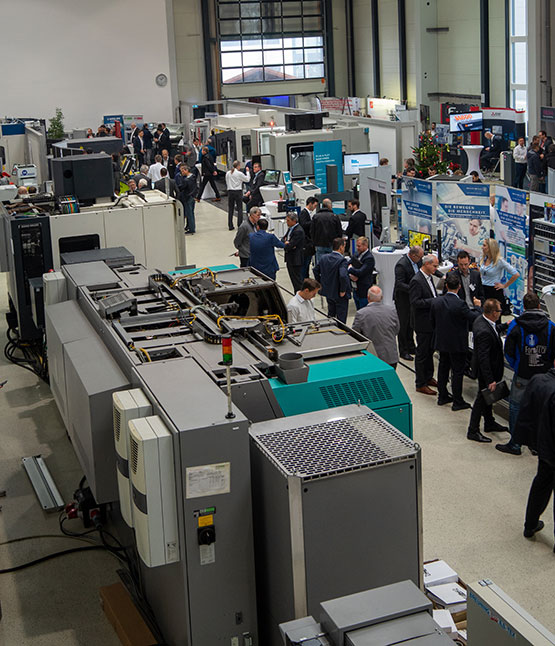

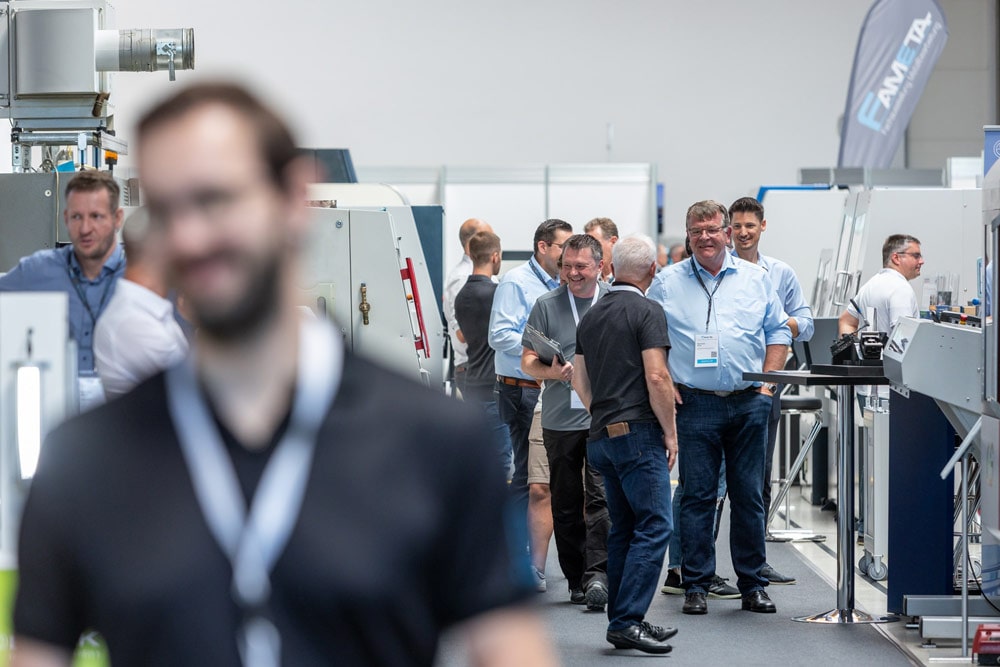

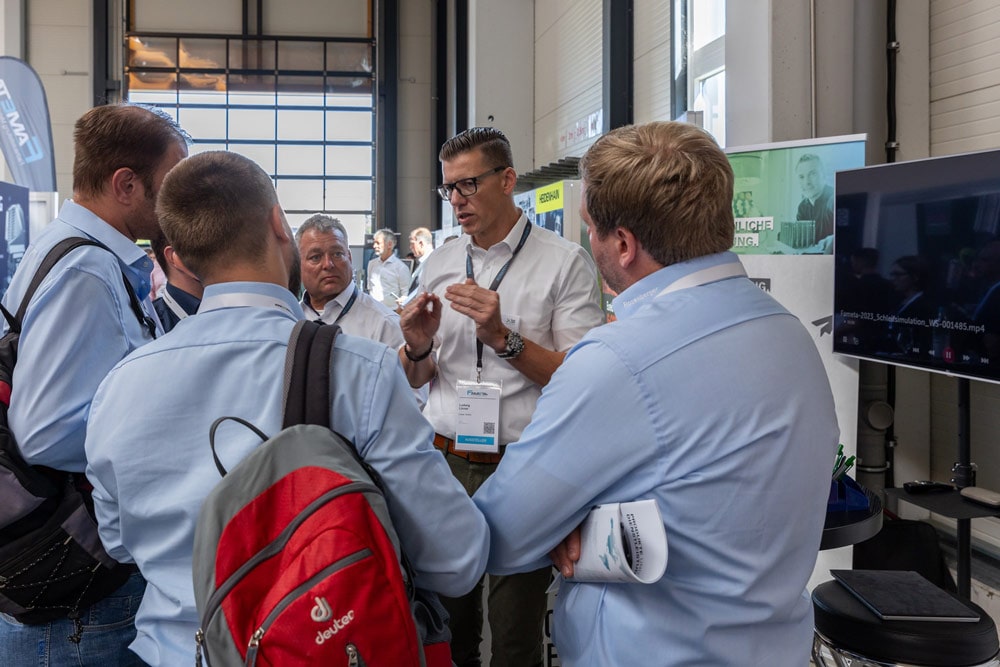

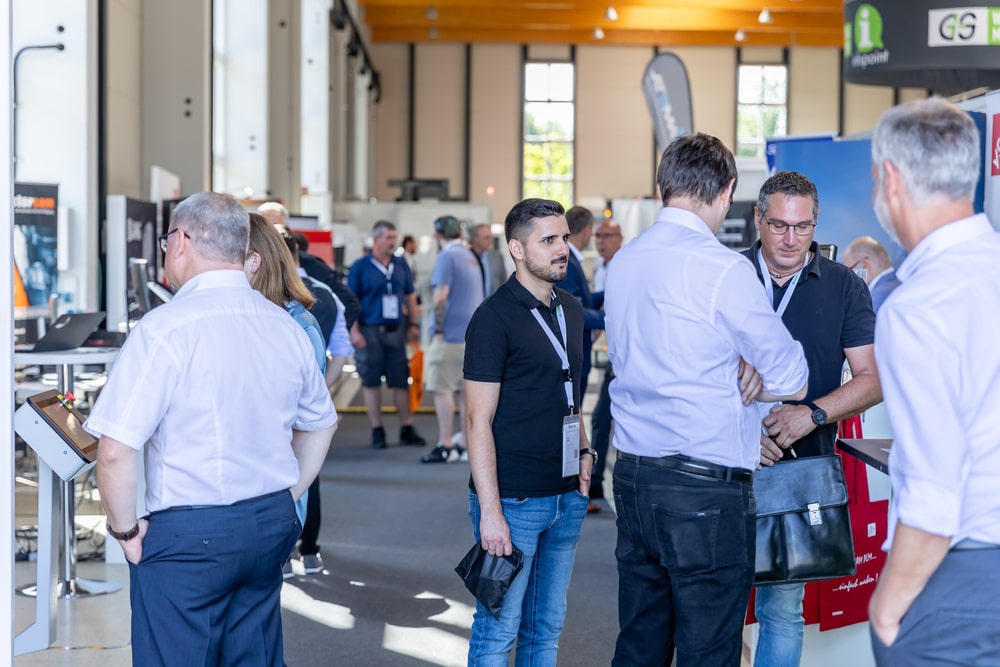

A key feature of the metalworking trade fair is its concept as an event with a high level of expertise among the participants, not as a large-scale mass-commercial event. The trade fair is aimed specifically at specialists: machine operators, CNC programmers and managers from machining companies in Germany, Austria and Switzerland. The aim: direct, personal contact in a cosy atmosphere between manufacturers and producers - away from the anonymous hustle and bustle of trade fairs.

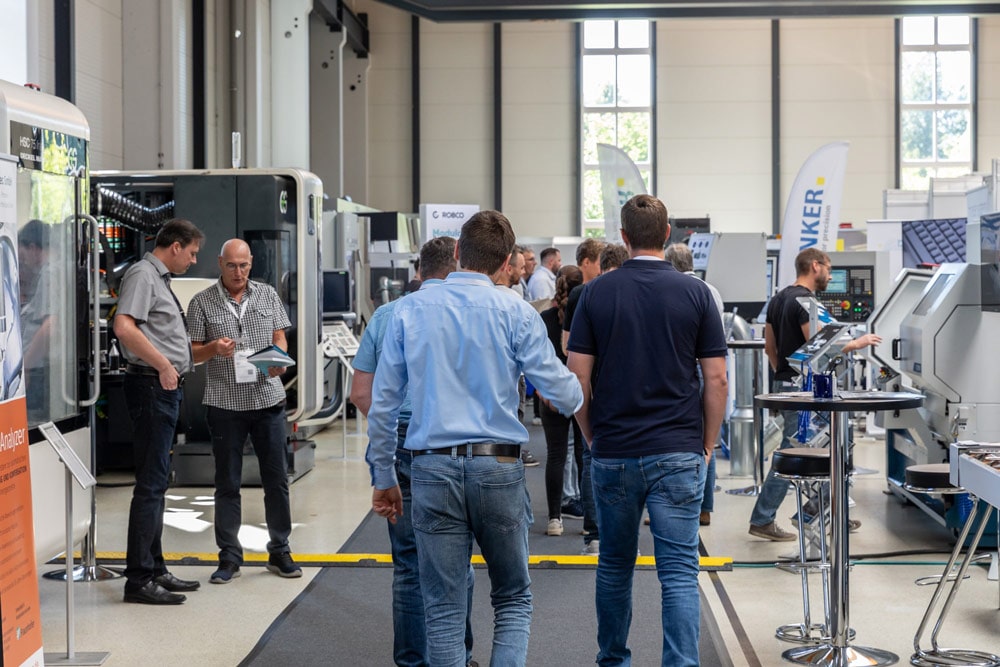

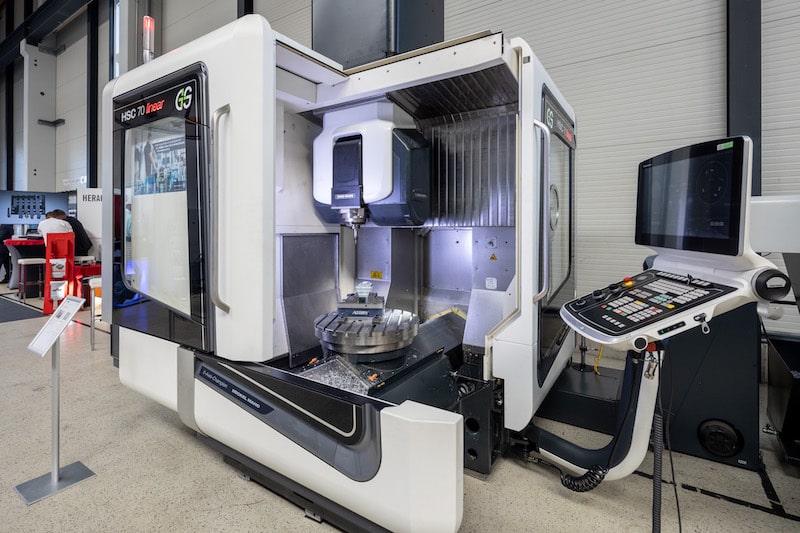

The ongoing demonstrations on 67 live machine tools met with great interest. The diverse exhibition programme includes automation and robot solutions, as well as industrial software, tool and clamping systems, peripheral devices, extraction technology and operating equipment. A complete list of exhibitors can be found here.

"In its fifth year, FaMeta has reached a dimension that makes us very happy and motivates us to become even better," says Holger Kösler. "For the next event, we are now taking a longer approach to take the planning, organisation and running of FaMeta to a new level." The next FaMeta will therefore not take place for another two years, from 23 to 25 June 2027 in Olching.

Atmosphere

Our exhibitors and visitors appreciate the personal ambience. Exchange experiences with supplier plants, our sales professionals or machine operators from the industry. No mass processing like at the big trade fairs.

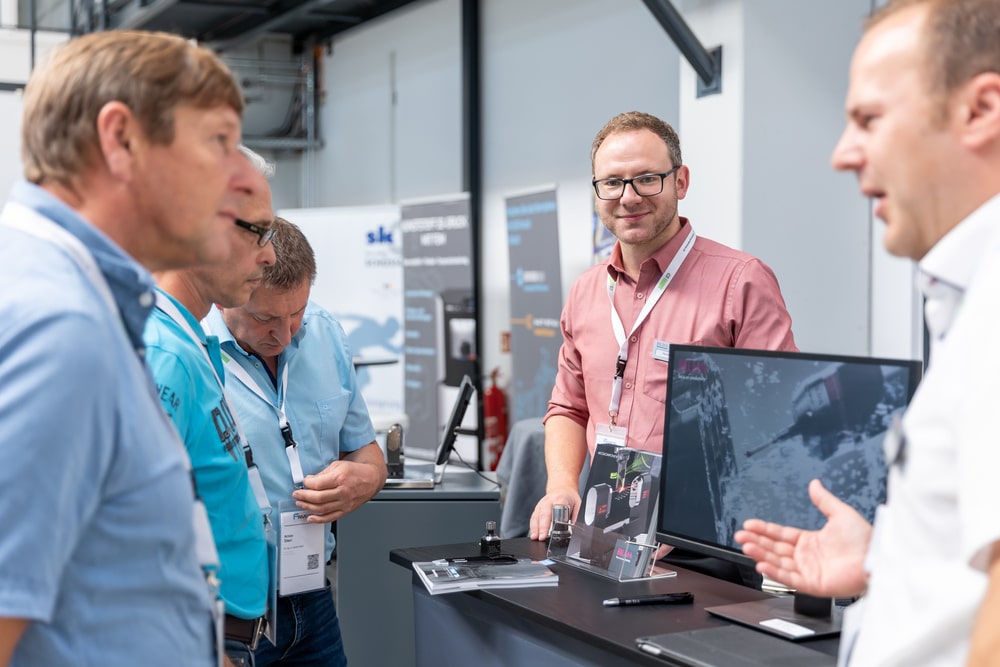

Innovation

Whether it's new generations of machine tools, accessory solutions or software innovations to make everyday life in your company easier, you'll find what you're looking for here.

Under voltage

Of course you should also see chips flying! New exhibits and young used machine tools under power and under chip!

Opening hours

The opening hours of FaMeta27 will be announced later.

Culinary

Food and drink keeps body and soul together. Our Bavarian beer garden will spoil you with regional delicacies and draft beer.

Workshops

In addition to product news and innovations in software and accessories, we also offer you the opportunity to participate in seminars. Expand your knowledge and get involved yourself in our workshops.

Impressions

Get an impression yourself!

- All

- Overview

- Visitors

- Machines